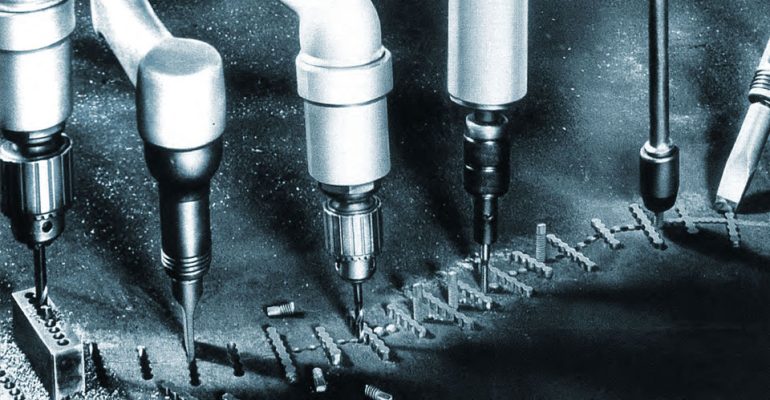

Společnost je tradičním dodavatelem služeb oprav prasklých nebo ulomených strojních částí studeným procesem Metalock.

METALOCK je metoda oprav prasklých nebo ulomených litých ocelí a litinových strojních částí studeným procesem METALOCK. Tato metoda byla vyvinuta a patentována v šedesátých létech v Anglii a byla natolik úspěšná, že se rozšířila prakticky do celého světa. Pro Českou a Slovenskou republiku je držitelem licence společnost Strojírny a stavby Třinec, a.s.